Reporting

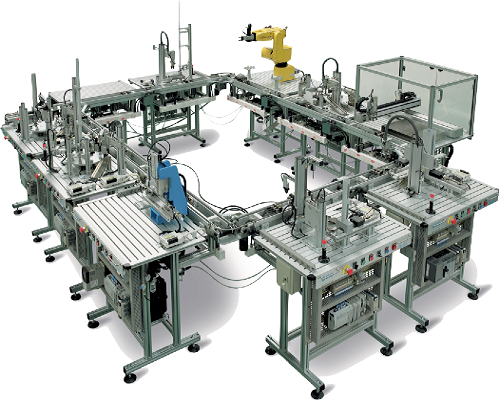

At EndisTech, we leverage Industry 4.0 technologies to transform our reporting operations, providing real-time insights and data-driven decision-making. By integrating IoT devices, advanced sensors, and machine learning algorithms into our production lines, we gather precise and continuous data on equipment performance, product quality, and process efficiency.

Our reporting system is designed to monitor every stage of production and supply chain, enabling automated data collection and analysis. This allows for instant reporting on key performance indicators (KPIs), production volumes, equipment utilization, energy consumption, and more.

Through our Industry 4.0 application, we ensure that stakeholders at all levels—management, operations, and maintenance teams—have access to accurate, up-to-date information at their fingertips. Customizable dashboards and automated alerts provide proactive insights, helping us identify and resolve issues before they escalate, optimize resource allocation, and improve operational efficiency.

Our commitment to real-time, data-driven reporting empowers us to not only track performance but also predict potential problems, leading to smarter decisions and enhanced productivity. With Industry 4.0, we are not just reporting the past; we are forecasting the future.