Machine Automation

Machine automation aims to automate production machinery and equipment. This type of automation is commonly used in factories, production lines, and assembly processes. Machine automation systems can include various mechanical and electronic devices, such as industrial robots, CNC machines, conveyor belts, and automation equipment. This type of automation is used to increase production efficiency, reduce labor costs, and improve product quality.

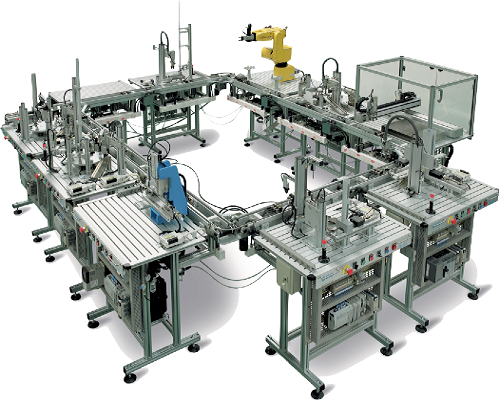

Let’s explain machine automation systems with an example for easier understanding: Consider a furniture factory and the production process of wooden doors.

You first designed an automation system to integrate the factory’s production line, and the key component of this system is PLCs, which will organize the production processes.

Then, to monitor the production line, you selected sensors. For example, optical sensors check the size and quality of the doors, while laser sensors inspect the doors for smoothness.

Next, you arrive at the most important part: using a CNC (Computer Numerical Control) machine to cut and shape the doors. Here, the PLCs determine the correct cutting and shaping instructions for each door, and the CNC machine follows these instructions precisely to complete the task.

Finally, you need specialized automation software to integrate all these technologies. This software allows you to program the PLC, coordinate the sensors, and monitor the process. It also provides factory operators with a user-friendly interface, enabling them to easily observe the production process and intervene when necessary.

In this way, the automation project enhances the factory’s sustainability and competitiveness while fully automating the entire process.

We provide services as an expert team, guiding businesses from the design and implementation to the commissioning of these automation systems.