Process Automation

Process automation ensures that industrial businesses’ production processes are more efficient and risk-free. Automation systems such as PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition) are systems that help successfully manage these processes.

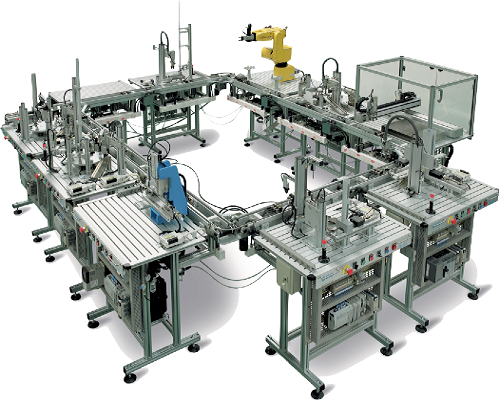

To make the systems easier to understand, let’s explain PLC and SCADA systems with a single example:

For example, in a beverage factory, you set up a PLC system, which allows you to automate processes such as filling bottles, capping them, labeling, and packaging. These systems also work integrated with sensors to improve product quality and reduce the chances of errors.

Now, let’s say you’ve also set up a SCADA system in the factory. With this system, you collect data from the production process, such as the filling amount, temperature, and production speed of each bottle. Through visualization, you can monitor this data in real-time, allowing operators to intervene when necessary.

With all this data, you gain insights on how to optimize your operations. When SCADA detects a potential error, it sends rapid and successive alerts to operators, for instance, immediately notifying them of a machine malfunction or a filling error.

We provide services as an expert team, assisting businesses from the design to the implementation and commissioning of these automation systems.